As I was putting the shop together I was trying to envision what tools I would need and how much space I would need to accomplish my goals. One of my goals is to be able to build several of the replacement parts such as pick-guards, guitar necks, guitar bodies, paint handles, etc. Doing this by hand is possible, but would take a considerable amount of time. As I scoured the Internet looking for ideas I came across a video on CNC Routers. The video piqued my interest.

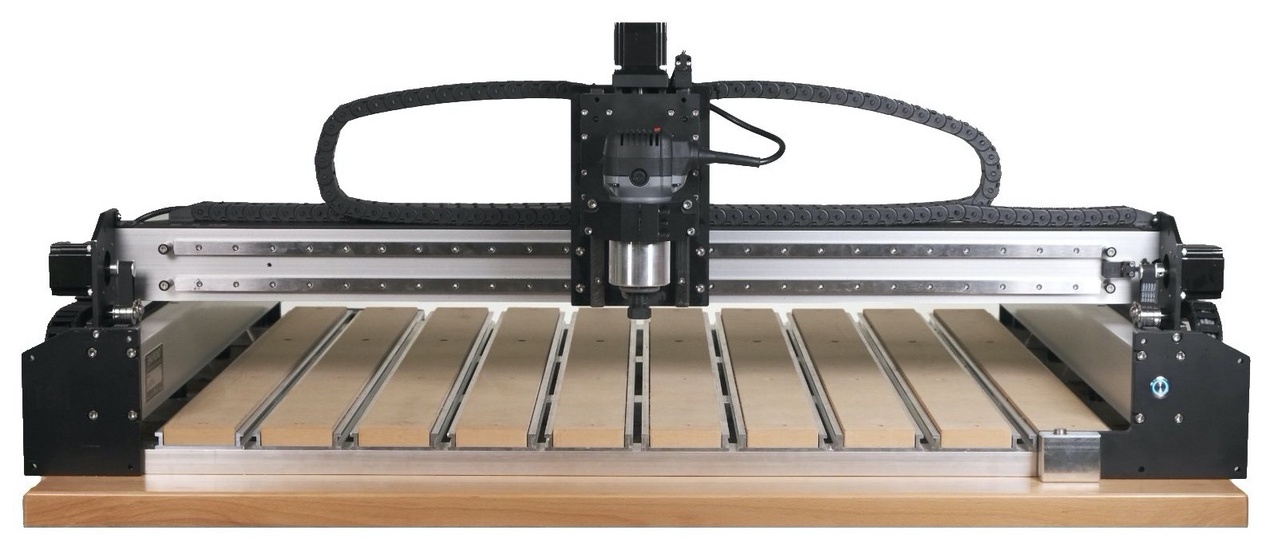

I began to research CNC Routers and what they could do for me. I learned that not only can they cut/route/engrave most wood materials, but a CNC router can also be used with Acrylic, Plexiglas, Aluminum, brass, and other metals and plastics. Router bit manufacturers have a bit for just about everything. After many hours of research, I narrowed my search down to the Shapeoko Pro XXL CNC router made by Carbide 3D. There are many things to consider when buying a CNC router, but here is what it came down to for me.

I began to research CNC Routers and what they could do for me. I learned that not only can they cut/route/engrave most wood materials, but a CNC router can also be used with Acrylic, Plexiglas, Aluminum, brass, and other metals and plastics. Router bit manufacturers have a bit for just about everything. After many hours of research, I narrowed my search down to the Shapeoko Pro XXL CNC router made by Carbide 3D. There are many things to consider when buying a CNC router, but here is what it came down to for me.

The company has a great reputation and as you watch videos on CNC router topics, you will see many woodworkers are using either Shapeoko or Nomad brand routers. Both of these CNC machines are made by Carbide 3D. Carbide 3D builds each machine right here in the USA and the support is US-based as well. They make their own version of CAD (computer-aided design) software called Carbide Create and Carbide Motion for CAM (computer-aided manufacturing). CAD is where you draw your design and CAM is the software that takes the design and sends it to the CNC router. The basic version of Carbide Create is free to download and use. This will give you 2D design capabilities. Their products also support using industry-standard CAD systems such as Fusion360 by Autodesk. They have instructions for assembling the machine in the form of a paper and PDF installation guide, and a video walkthrough of the installation. They also have customer service agents that can help you with questions along the way.

I purchased the CNC machine through Carbide3d’s website. It was about 6:00 PM one evening when I decided to purchase the system. The next morning around 8:00 AM I logged into my computer and checked my email. I already had a tracking number for the 2-box shipment that was on the way. Following shortly after that were notifications that some of the extras I ordered were being shipped as well. I was impressed by the speed of their team to prepare and ship the system. I had the main system on my doorstep two days later.

In all, I spent about 12 hours working on the installation. I could have completed the project sooner, but there were setbacks due to older documentation and an outdated video. Let me explain.

The machine arrives in 2 large boxes. When you open up the boxes, these boxes contain the parts needed for each step of the installation process. You can open an installation guide, PDF, or start the installation video and off you go. I used the guide and the video, which were very helpful. You are shown the parts and how to begin assembling the first step. However, some of the parts were updated in the design and they didn’t look like the ones in the guide or video. So it takes time to ensure you have the parts oriented in the correct direction. There are additional holes and mounts added, but nothing in the documentation to explain what they are for. No addendum. At one point in the installation, a part I was told to use (L-shaped bracket) wasn’t in the box. No information was provided on the missing bracket. Later I learned that they replaced two of the L-shaped brackets with one H-shaped bracket. Again, no information in the boxes telling me about the bracket change. There were a few other issues along the way and I was able to work through them.

I was able to place several calls to technical support. Whenever I called I had to leave a message, but someone usually called me back within about 20 minutes, The team was very helpful and walked me through all my issues. During one call I had an operation issue (operator issue) and they connected to my cell phone through a support tool so I can show them what was happening. Then they walked me through the resolution. Carbide 3D has training for their software and a video on how to get started with their first five projects. You can tell the people who put the video together have forgotten what a new user to CNC would want to know. In some areas, they moved fast through the video, and some of the detail they flew past would have been helpful for first-time users.

I was able to place several calls to technical support. Whenever I called I had to leave a message, but someone usually called me back within about 20 minutes, The team was very helpful and walked me through all my issues. During one call I had an operation issue (operator issue) and they connected to my cell phone through a support tool so I can show them what was happening. Then they walked me through the resolution. Carbide 3D has training for their software and a video on how to get started with their first five projects. You can tell the people who put the video together have forgotten what a new user to CNC would want to know. In some areas, they moved fast through the video, and some of the detail they flew past would have been helpful for first-time users.

One thing I do wish they would have offered is a first-year free or discounted price on their Pro version of Carbide Create. The Pro version is needed to do 3D modeling when making guitar necks and other guitar-related parts.

Even though I had a few setbacks during the installation, the experience has been positive. I communicated my issues to Carbide 3D and I hope they can use my feedback to improve their customer experience during setup. There is a lot to learn about using CNC routers, but much of it is getting through each topic for the first time. I am looking forward to many ways to use this CNC router in my little guitar shop. ?